Advantages of Bearing Induction Heaters

Introduction

Induction heating is essential for precise and efficient material heating, especially for electrically conductive materials such as bearings and metals. This non-contact method has paved the way for a safer, faster, and more controlled approach compared to traditional heating methods like ovens, oil baths, or gas burners. In this article, we will talk about induction heaters, with a special focus on bearing induction heating, a process that not only ensures safety but also plays a pivotal role in preventing premature bearing failure.

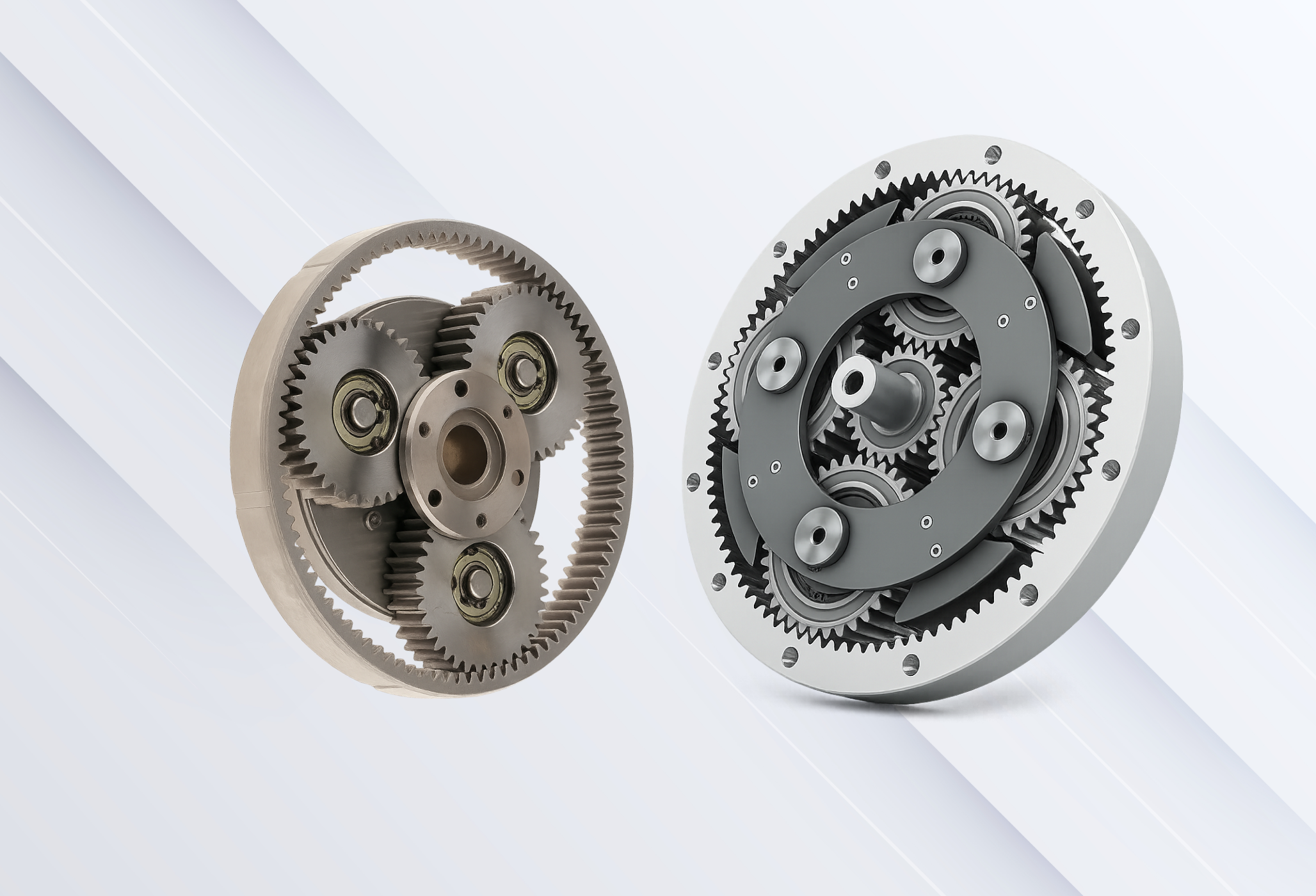

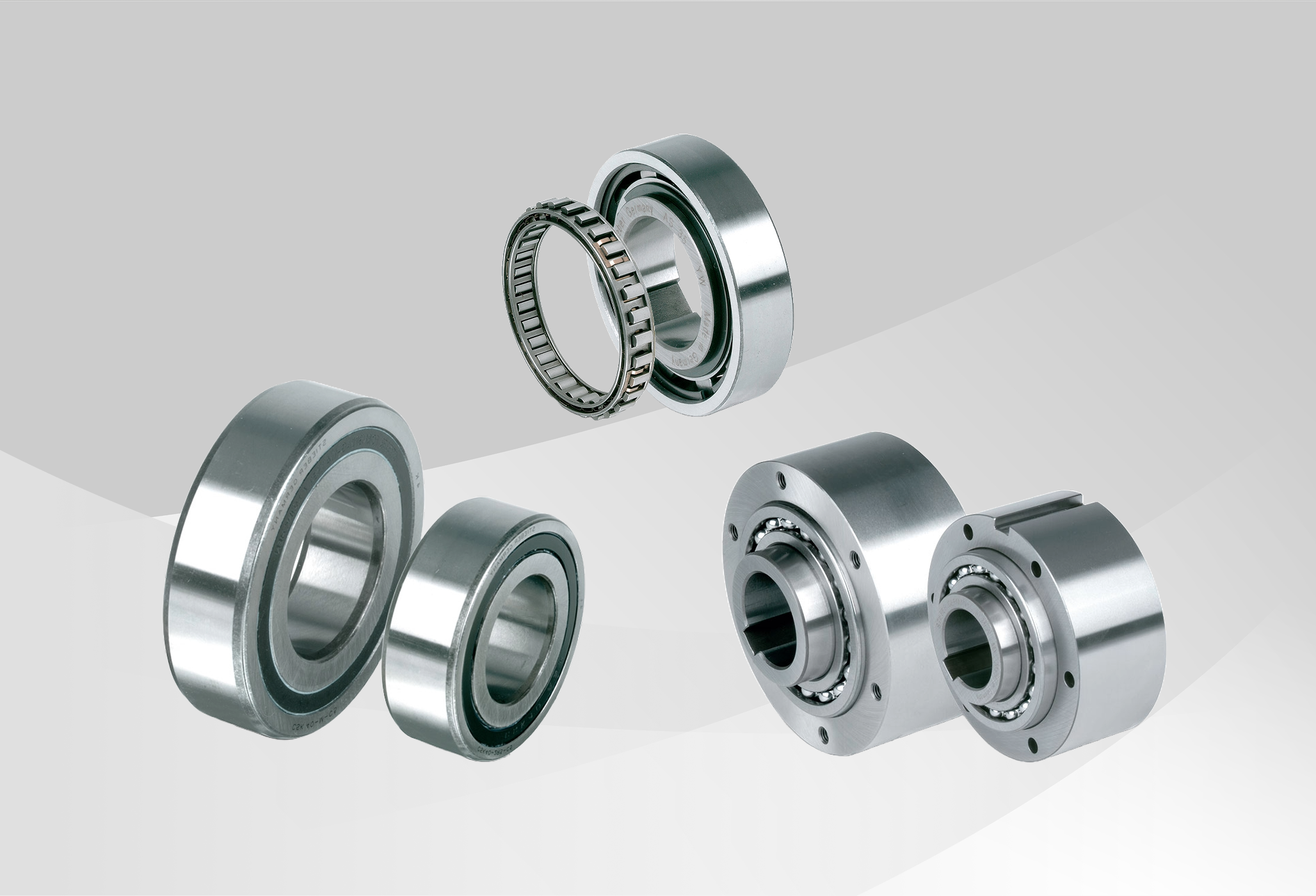

Bearing Induction Heating

Bearing induction heating lets users properly fit bearings onto a shaft. The induction heater generates an oscillating electrical current, creating a magnetic field that, when the bearing or metal is placed within it, induces eddy currents. This, in turn, causes the bearing to heat up and expand. Once the induction bearing heater reaches the precise temperature required, operators can safely remove the hot bearing with appropriate safety gear and place it onto the shaft. As the bearing cools down, it contracts to snugly fit onto the shaft, ensuring a secure and precise placement.

Advantages of Bearing Induction Heaters

-

Safety: Bearing induction heaters provide a secure and clean method for affixing bearings to a shaft. The non-contact process eliminates the risks associated with traditional methods, such as odor and smoke nuisance, making it a safer choice for operators and creating a healthier working environment.

-

Efficiency and Speed: These tools offer a quick and efficient way to place bearings securely onto a shaft, reducing downtime and increasing overall operational efficiency. The controlled heating process ensures a precise fit, eliminating the need for adjustments post-installation.

-

Preventing Premature Bearing Failure: Improper installation is a leading cause of premature bearing failure, accounting for over 16% of cases. The lack of proper tools and knowledge often subjects new bearings to high levels of stress and subsurface damage, making failure inevitable. Controlled induction heating emerges as the best practice for bearing mounting, ensuring stress-free heating and preserving the original bearing lubrication.

-

Variety and Portability: Bearing induction heaters come in various sizes, including induction heating generators, handheld induction heaters, and others, serving different industrial needs. Additionally, portable bearing induction heaters provide flexibility for on-the-go maintenance tasks, offering a versatile solution for diverse applications.

Conclusion

In conclusion, bearing induction heaters offer a safe, efficient, and environmentally friendly alternative to traditional methods, ultimately contributing to extended bearing life and enhanced operational performance.

HVH Industrial Solutions is an authorized distributor of Simatec and BEGA Special Tools, and we offer a wide range of their induction heaters. We work closely with their engineering team to provide superior customer service and engineering support.

If you have any questions, write to us via live chat or call or send us a quote request. The HVH team is always ready to help you.